We wrote a program on ESP32 for an electrode position paint system and also developed a mobile application for Android and iOS to control, monitor, and analyze the data collected during the painting process.

A. DATA LOGGER:

-

We make a data logger and an electrodepositing paint system with small voltage, temperature, and DC current sensors that are powered by batteries and are connected to Android and iOS app.

-

Logger can record the summary data every second and collect the data in flash after every 5 minutes.

-

Data will be send it to the mobile app over BLE for post-processing, report & chart generation if it is armed by the user

Program For Firmware:

-

Create a Method to save all run data in one file.

-

It allows the temperature sensor to acclimate from ambient (~20 C) to the temperature of the paint bath, which is generally > 30 C.

-

Battery Charging Mode: When the Unit is placed on its’ charging pad the LiPO battery management chip handle charging. As per the business logic, at this moment the BLE is not connected and the unit will not arm during this time.

-

Wake up from Deep Sleep & Connect to BLE Central: When the logger is removed from its’ case and ambient light falls on the Charging unit is awakening from sleep, it will connect with a BLE Central device to set the parameters for the run and also Arm the unit.

-

Logging: Logging is triggered by a user-selectable voltage set point or loss of ambient light. During the painting process, the measured temperatures go below the set point, but our system has a Time Zone correction to determine when to stop the charging.

-

After a Logging event: The unit looks for a BLE Central to connect to. Once this happens then the run data file opens. Post-processing occurs (calibration, scaling, etc) details of the run display on the screen of the BLE Central device.

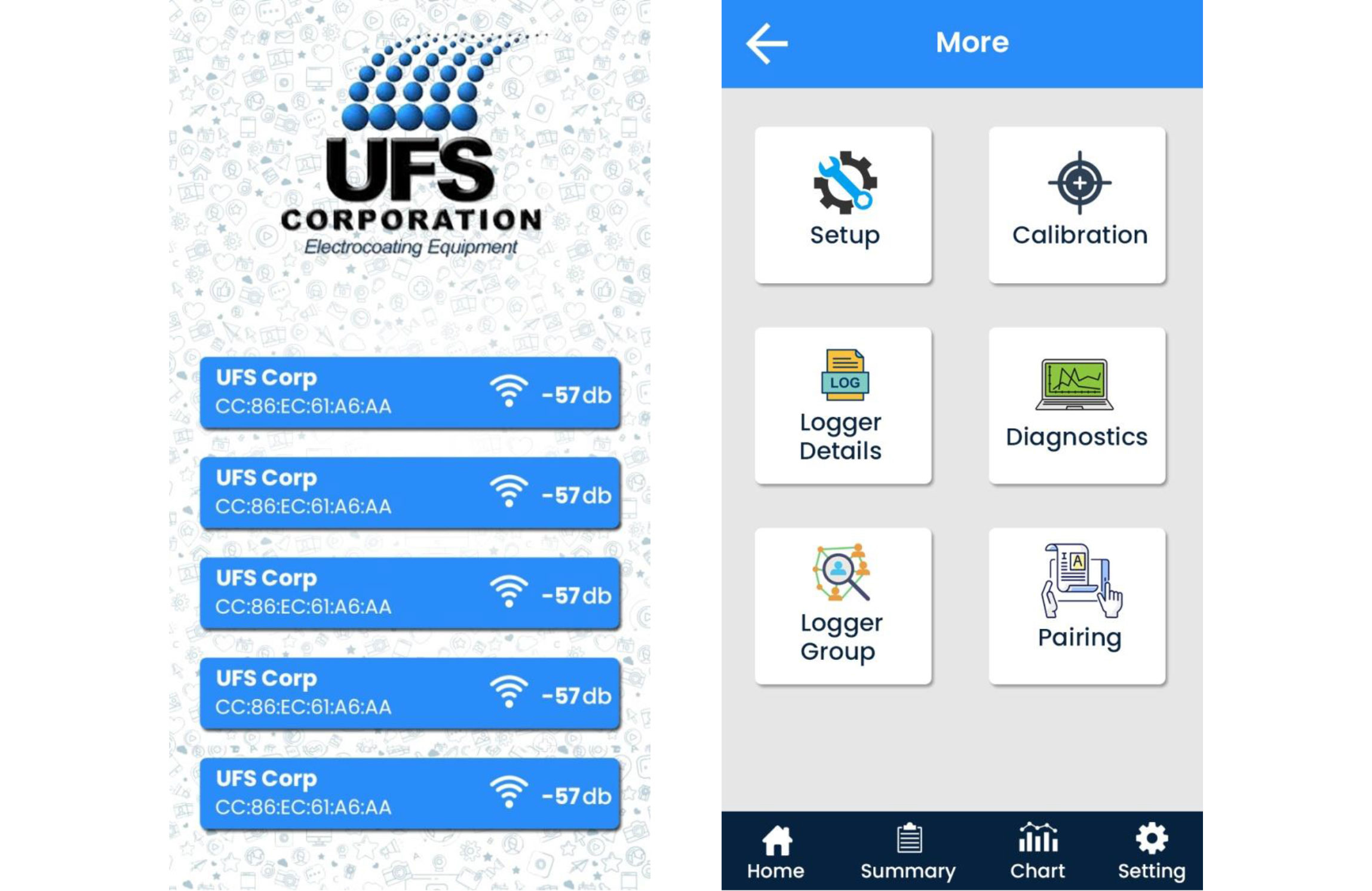

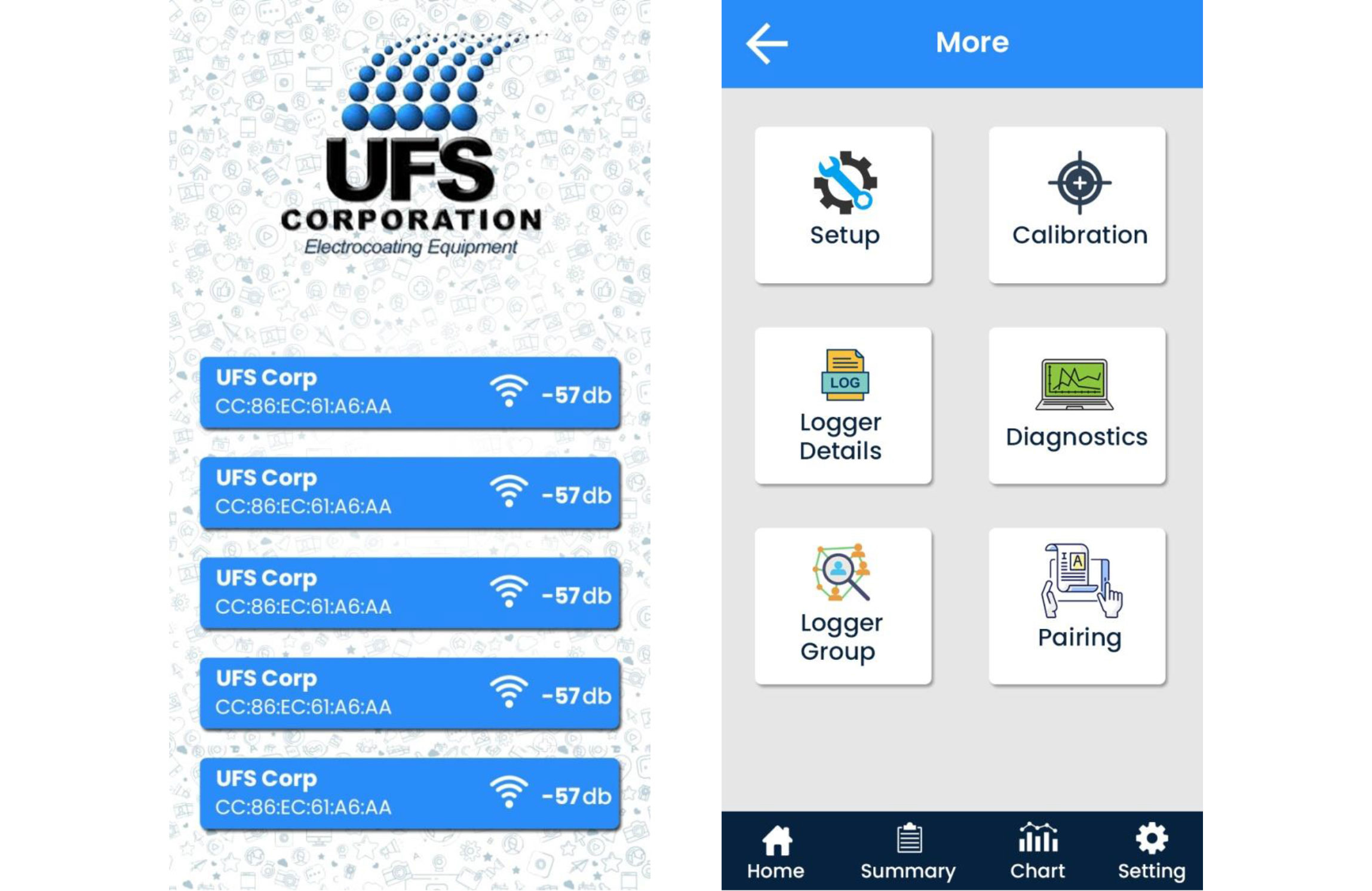

B. BLE App:

-

For the BLE app, we have created native Android & iOS Applications, named UFS Corporation.

-

For the combined results of up to 7 loggers (i.e. peripherals) together with a BLE Central (i.e. Phone), we add the following features in the application:

-

To activate the device to read its parameters, we added the toggle button to set on ambient light or voltage trigger.

-

After triggering the board, a blue LED starts flashing where the data summary in the Run data summary page of the App is shown.

-

Till this point, you can see the data of the sensors and also set the threshold for voltage trigger, Interzone timeout, etc.

-

To start the logging, we added a button to the arm and then green LED flashed indicating the logging has started.

-

The data logger puts the data in flash every 5 minutes and sends it to the BLE app to make the file.

-

In case the logging doesn’t stop the logger overwrites the data and sends it to the BLE app to append that data.

-

If the logging stops in between or the device is unarmed in between, the logger saves the collected data.

-

The app saves the Summary Report to a local Network, to an attached Storage device or to a Cloud provider.

-

The app displays 300 seconds worth of data on a small phone as well asdirect the chart to a local printer.

-

App has the ability to upgrade firmware OTA

-

After unarming the blue LED starts to flash.

-

If the battery is not low, then the Blue LED starts to flash indicating the BLE radio is On (acting as a peripheral).

-

Once a BLE Central is able to connect the Blue LED turns solid.

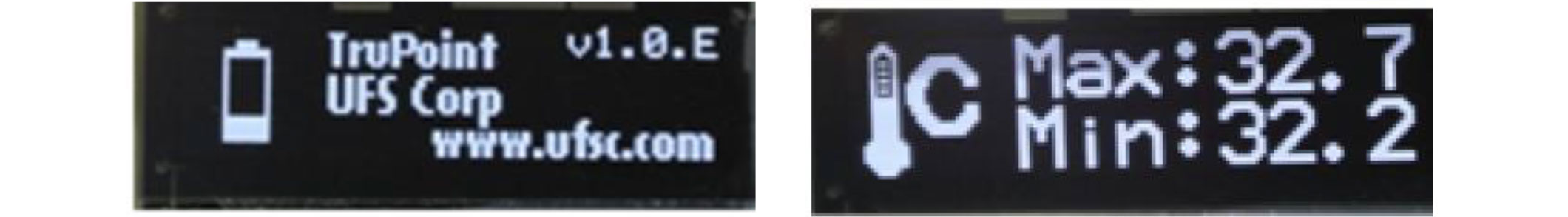

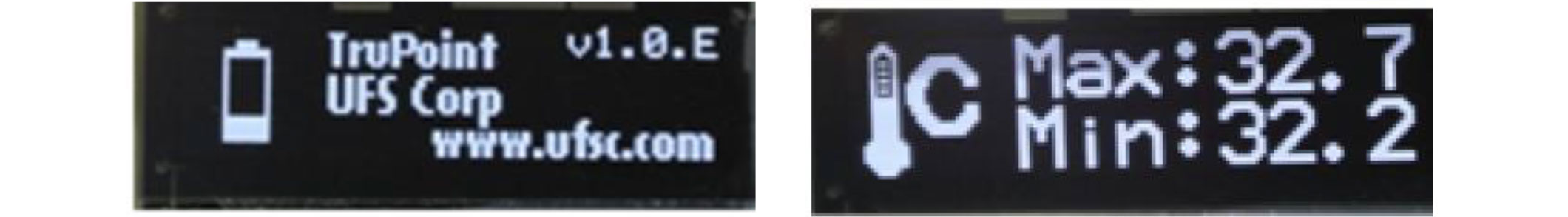

C. OLED Screens:

As requested by clients, we use existing icons to reduce the use of English language text for

- DC V max

- AC V max

- Temperature - low &. High

- V

- Create a new # Coulombs icon similar to others.

- Create a new DC A Peak con using DC V and replace ‘V’ with ‘A’.

We also provide a diagnostic routine; when μP pin is pulled Low, a diagnostic routine is started and results display on the OLED. Diagnostic Routine consists of

-

Times unit has been awakened

-

minutes in On state

-

data runs

-

Of times of logging termination due to low battery V

-

Any current errors

-

Error log history

-

Historical Max Temperature measured: Liquid/Air; Ware,& PCB.

-

Historical Max DC V

-

Historical Max AC V

-

Historical Max DC Current Historical Max # Coulombs

-

Historical Max of Total time > 8 V

-

Historical Max of μP die temperature

-

Max data run duration

-

Tally of a number of minute’s battery was being charged.

-

Tally of Total time > 8 accumulated for all data runs

-

Technical issues not resolved

-

Plug to keep paint off charging contacts.

After finishing a run, the unit activates BLE and sends the raw data (in the form of a CSV file) to "post processing," which includes calibration, scaling, report formatting, saving, retrieving, and comparing to previous data runs.

Analog inputs are calibrated on a regular basis, and calibration files are saved in RAM using the BLE app.

The temperature is noted as an integer, but displays in the BLE App as a decimal point as app divides the integer by 10 to produce a decimal point.

The calibration coefficient is calculated and saved within the module.

The App is able to aggregate the data from this cohort to produce a single file that is aligned by the data and timestamp.

D. Hardware Summary:

-

Silicon Labs PN #BGM220PC22HNA FCC approved Module

-

Small footprint so use 2 PCBs with a battery in between the boards

-

Pogo pins type charging method with a ~500 mAHrLiPo single cell battery

-

IP-67 3D printed case with clear cover

-

Phototransistor to detect ambient light

-

RGB LED to indicate: low battery/charging; BLE available/connected; color code when armed

-

32 x 128 B&W SPI OLED (Crystalfontz PN CFAL12832D-B)*

-

~2 cm^2 metal plate that is grounded through magnet - a paint film will form on its’ exterior.

-

Reset button

-

Internal pad when shorted to GND will start diagnostic routine.

-

12 Bit ADC with 0 - 3V3 input range

-

I2C display CFAL12832C0-01B-W. OLED display may be deleted after beta testing if BLE connection renders it redundant.

Mean Stack Development

Mean Stack Development

Vue JS Development

Vue JS Development

Javascript Development

Javascript Development

React JS Development

React JS Development

Angular JS Development

Angular JS Development

Next JS development

Next JS development

Java Development

Java Development

Python Development

Python Development

Django Development

Django Development

Cherrypy Development

Cherrypy Development

C# Development

C# Development

ASP.NET Development

ASP.NET Development

NodeJS Development

NodeJS Development

Laravel Development

Laravel Development

CodeIgniter Development

CodeIgniter Development

Zend Development

Zend Development

Ruby on Rails Development

Ruby on Rails Development

CakePHP Development

CakePHP Development

PHP Website Development

PHP Website Development

Symfony Development

Symfony Development

Drupal Development

Drupal Development

Joomla Development

Joomla Development

Wordpress Development

Wordpress Development

.NET Nuke Development

.NET Nuke Development

Kentico

Kentico

Umbraco

Umbraco

.NET MAUI Development

.NET MAUI Development

Xamarin Application Development

Xamarin Application Development

iOS Application Development

iOS Application Development

Android Application Development

Android Application Development

Android Wear App Development

Android Wear App Development

Ionic Development

Ionic Development

Universal Windows Platform (UWP)

Universal Windows Platform (UWP)

Kotlin Application Development

Kotlin Application Development

Swift Application Development

Swift Application Development

Flutter Application Development

Flutter Application Development

PWA Application Development

PWA Application Development

Offshore Software Development

Offshore Software Development

Custom Application Development

Custom Application Development

Front-End Development

Front-End Development

Full Stack Development

Full Stack Development

AI & Machine Learning

AI & Machine Learning

Custom CRM Solutions

Custom CRM Solutions

Flask Software Development

Flask Software Development

Electron JS Development

Electron JS Development

ChatGPT Development

ChatGPT Development

Magento Development

Magento Development

Magento 2.0 Development

Magento 2.0 Development

Magento Enterprise

Magento Enterprise

Shopping Cart Development

Shopping Cart Development

Prestashop Development

Prestashop Development

Shopify Development

Shopify Development

Open Cart Development

Open Cart Development

WooCommerce Development

WooCommerce Development

BigCommerce Development

BigCommerce Development

NopCommerce Development

NopCommerce Development

Virto Commerce Development

Virto Commerce Development

AspDotNetStorefront Development

AspDotNetStorefront Development

RaspBerry Pi

RaspBerry Pi

Firmware Software Development

Firmware Software Development

ESP 32 Software Development

ESP 32 Software Development

Embedded Development

Embedded Development

Internet of Things

Internet of Things

Nordic Development

Nordic Development

.NET Application Development

.NET Application Development

Microsoft Dynamics CRM

Microsoft Dynamics CRM

VB .NET Development

VB .NET Development

Sharepoint Migration

Sharepoint Migration

ASP.NET Core Development

ASP.NET Core Development

ASP.NET MVC Development

ASP.NET MVC Development

AJAX Development

AJAX Development

Agile Development

Agile Development

Microsoft Bot

Microsoft Bot

Microsoft Blazor

Microsoft Blazor

Microsoft Azure Cognitive

Microsoft Azure Cognitive

HTML 5

HTML 5

UI/UX Design

UI/UX Design

Graphic Design

Graphic Design

Adobe Photoshop

Adobe Photoshop

XML Application Development

XML Application Development

Cloud Computing Solutions

Cloud Computing Solutions

Azure Cloud App Development

Azure Cloud App Development

AWS Development

AWS Development

Google Cloud Development

Google Cloud Development

SQL Programming Development

SQL Programming Development

MySQL Development

MySQL Development

MongoDB Development

MongoDB Development

Big Data

Big Data

Robotic Process Automation

Robotic Process Automation

Social Media Marketing

Social Media Marketing

Search Engine Optimization

Search Engine Optimization

QA Testing

QA Testing

Software Testing

Software Testing

Software Security

Software Security

Maintenance And Support

Maintenance And Support

I.T. Consulting Services

I.T. Consulting Services

Business Intelligence

Business Intelligence

YII Development

YII Development

Data Analysis

Data Analysis

Alexa Skills Development

Alexa Skills Development

On Demand App for Mobile repairing services

On Demand App for Mobile repairing services

On Demand App for Car Service Booking

On Demand App for Car Service Booking

On Demand App for Cleaning Services

On Demand App for Cleaning Services

On Demand App for Pharmacy

On Demand App for Pharmacy

On Demand Dedicated Developers

On Demand Dedicated Developers