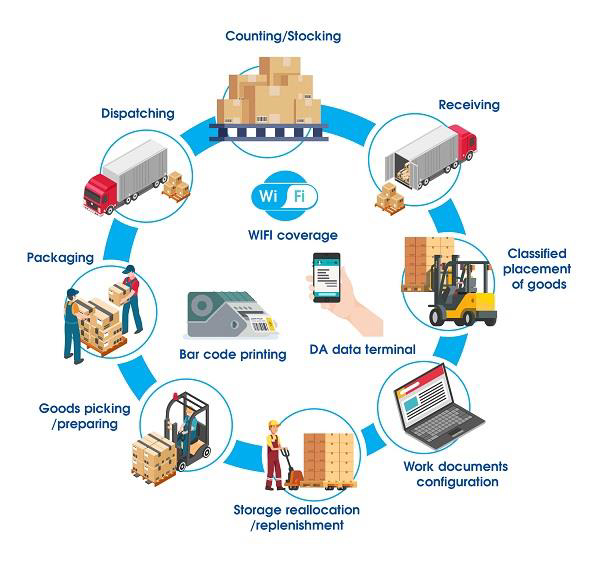

Detailed features and functions of this warehouse management software include:

Receiving

The functions and modules for the receiving module of warehouse management software are as below:

-

Receiving of orders

-

Multiple types of receipt orders

-

Specialty receipt support

-

Allow/restrict partial case receipts

-

Reverse and voiding of receipts

-

Appointment scheduling

-

Dock scheduling

-

Cross-docking

-

Yard management

-

Directed put-away

-

Returns management

-

Customer return

-

RTO return

-

Vendor data tracking

-

Label verification

-

Label generation

-

Palletize LPNs on receipt

-

Mobile RF barcode scanning and app/Smartphone support

A: Inventory Management

Inventory-focused warehouse management system modules are intended to ensure that you always have accurate inventory counts while also predicting when you will need to reorder. We have added the following functions to this section of the software to accomplish this:

-

Services

-

Login /Sign-up (Client)

-

Replenishment

-

Auto stock allocation on a pro-rata basis, reduce damage with SUF and PUF based indents.

-

Provision for setting outlet-wise reorder quantity, minimum and maximum stock level for all items.

-

Supports Replenishment based on the indent request received from the outlets, supports both franchisee and own outlet model.

-

Outlet-wise real-time inventory monitoring system at HQ facilitates effective replenishment by sensing the current stock positions.

-

Cycle counting

-

Serial tracking

-

Lot tracking

-

Quality control

-

Task interleaving

-

Periodic inventory snapshots

-

Data tracking across skids, LPNs, packages, and units

-

Misc. inventory labeling and tracking support

-

Bar Code Scanner Auto-Adding New Retail Purchases from Mobile phone

-

Material handling to pick lanes, combinations

-

Browser Extension Auto-Adding New Purchases

-

Location-defined SKUs

-

Adjustable form fields such as lot #, owner, location.

B: Order Fulfillment And Management

Order fulfillment is the most important warehouse activity for any company. It encompasses the entire process, from receiving an order to delivering it to the customer. We provide a lot of functionality here, and the majority of it is standard.

-

Automation and Artificial Intelligence

-

Automated Purchase Orders

-

Automated Work Orders Pick tickets

-

Work-in-process materials tracking

-

Inventory availability

-

Electronic Order entry

-

Rule-based (smart) order routing

-

Rule-based allocation tracking and configuration

-

Rule-based restrictions

-

Manifest print

-

Label and invoice print

-

Unify online and offline orders

-

Allocation tracking and management on the component level

-

Kitting & Assembly

-

Parts requirements

-

Automated inventory updates

-

Scan packing

-

Inspection and auditing in kits, batches, cartons

-

Consolidation by shipment or order

-

Pack and hold support

-

Shipping label generation including Skid, LPN, and UCC

-

Package and content labels

-

Price stickers

-

Customized font, size, etc.

-

Distributed order management

-

Fulfillment tracking and audits

-

Customer ship-top information storage and tracking

C: Advanced Picking and Shipping

As a business grows, its needs for picking, packing, and shipping change. These WMS requirements are intended to show you which modules you should think about as your operations scale. Based on how businesses currently categorize functionality, our 2020 update has relocated transportation management modules such as automated carrier selection to this group.

-

Wave management

-

Picking including Zone, Skip, LPN, Batch

-

Picking confirmation by type

-

Skid substitution support

-

Pack lists

-

Invoice creation and management

-

Sensor support and compliance (RFID especially)

-

Shipment notifications

-

Advanced picking options such as voice-enabled support

-

Captures asset tags during picking

-

On-demand replenishment to static, dynamic lanes

-

Two-stage replenishment support

-

Carrier selection tools and automation

-

Freight rating and calculators

-

Order consolidation support

-

Bid optimization

-

Route optimization

-

Freight payment

-

Carrier audit tools

D: Tracking and Analytics:

-

Tracking for your preferred KPIs across your warehouse

-

Daily performance and labor tracking

-

Real Time Tracking

-

Equipment usage and maintenance schedules

-

Warehouse layout optimization

-

Lead time understanding

-

Return-rate tracking

-

Inventory turn tracking

-

Ability to review historical data

-

Predictive analytics by category and product

-

Dashboards that are easy to read

-

Multi-lingual support

-

Tax Integration

E: Labour Management

Apart from the many unique features that identify and monitor physical materials and packages, this warehouse management software also includes labor management tools. Employees can clock in and out with easy-to-use QR codes or pins that keep a record of when they clock in and out of work. Some of these features have been added by us to WMS:

-

Employee Timestamps

-

Hours Tracking

-

GPS Enabled Tracking

-

Employee Performance Management

-

Labour KPI Management

-

Labour Forecasting

-

Schedule Optimization

F: RFID barcode scanning

Our superior barcode scanning system facilitates the receiving and shipping of inventory in warehouses. The barcode captures precise and detailed information about each item.

-

Returns handling

-

Serial bar-coding

-

SKU level bar-coding

G: Integrations with Standard Supply Chain Technology

The above-mentioned functionality is covered by our WMS, though this coverage can be a little tricky and is not necessarily limited to a specific WMS module.

-

E-commerce tool integration

-

marketing tools

-

email management

-

Accounting platforms like QuickBooks.

-

Payment system

-

Billing software

H: Administration Module/Staff of Admin

The user has access to customers, staff, and a 360-degree view of all activities, as well as complete control over the system, which requires an admin panel. The major sections are

-

Login: Standard login and Authentication

-

Dashboard: Show the complete overview of Disputes, Offers, Customers, Analytics, and various Notification alerts.

-

User Access Management: Create, Edit, and Control Access.

-

Manage Staff profiles: (inactivate profiles, if Staff does not comply with company policies)

-

Manage Customer profiles (inactivate non-compliant profiles)

-

Manage Audit

-

Dispute Management

-

Manage consumer agreements and privacy statements and CMS

-

Configurable system charges (or set various system protocols)

-

Reports (Various reports, the client will disclose the specs later)

Mean Stack Development

Mean Stack Development

Vue JS Development

Vue JS Development

Javascript Development

Javascript Development

React JS Development

React JS Development

Angular JS Development

Angular JS Development

Next JS development

Next JS development

Java Development

Java Development

Python Development

Python Development

Django Development

Django Development

Cherrypy Development

Cherrypy Development

C# Development

C# Development

ASP.NET Development

ASP.NET Development

NodeJS Development

NodeJS Development

Laravel Development

Laravel Development

CodeIgniter Development

CodeIgniter Development

Zend Development

Zend Development

Ruby on Rails Development

Ruby on Rails Development

CakePHP Development

CakePHP Development

PHP Website Development

PHP Website Development

Symfony Development

Symfony Development

Drupal Development

Drupal Development

Joomla Development

Joomla Development

Wordpress Development

Wordpress Development

.NET Nuke Development

.NET Nuke Development

Kentico

Kentico

Umbraco

Umbraco

.NET MAUI Development

.NET MAUI Development

Xamarin Application Development

Xamarin Application Development

iOS Application Development

iOS Application Development

Android Application Development

Android Application Development

Android Wear App Development

Android Wear App Development

Ionic Development

Ionic Development

Universal Windows Platform (UWP)

Universal Windows Platform (UWP)

Kotlin Application Development

Kotlin Application Development

Swift Application Development

Swift Application Development

Flutter Application Development

Flutter Application Development

PWA Application Development

PWA Application Development

Offshore Software Development

Offshore Software Development

Custom Application Development

Custom Application Development

Front-End Development

Front-End Development

Full Stack Development

Full Stack Development

AI & Machine Learning

AI & Machine Learning

Custom CRM Solutions

Custom CRM Solutions

Flask Software Development

Flask Software Development

Electron JS Development

Electron JS Development

ChatGPT Development

ChatGPT Development

Magento Development

Magento Development

Magento 2.0 Development

Magento 2.0 Development

Magento Enterprise

Magento Enterprise

Shopping Cart Development

Shopping Cart Development

Prestashop Development

Prestashop Development

Shopify Development

Shopify Development

Open Cart Development

Open Cart Development

WooCommerce Development

WooCommerce Development

BigCommerce Development

BigCommerce Development

NopCommerce Development

NopCommerce Development

Virto Commerce Development

Virto Commerce Development

AspDotNetStorefront Development

AspDotNetStorefront Development

RaspBerry Pi

RaspBerry Pi

Firmware Software Development

Firmware Software Development

ESP 32 Software Development

ESP 32 Software Development

Embedded Development

Embedded Development

Internet of Things

Internet of Things

Nordic Development

Nordic Development

.NET Application Development

.NET Application Development

Microsoft Dynamics CRM

Microsoft Dynamics CRM

VB .NET Development

VB .NET Development

Sharepoint Migration

Sharepoint Migration

ASP.NET Core Development

ASP.NET Core Development

ASP.NET MVC Development

ASP.NET MVC Development

AJAX Development

AJAX Development

Agile Development

Agile Development

Microsoft Bot

Microsoft Bot

Microsoft Blazor

Microsoft Blazor

Microsoft Azure Cognitive

Microsoft Azure Cognitive

HTML 5

HTML 5

UI/UX Design

UI/UX Design

Graphic Design

Graphic Design

Adobe Photoshop

Adobe Photoshop

XML Application Development

XML Application Development

Cloud Computing Solutions

Cloud Computing Solutions

Azure Cloud App Development

Azure Cloud App Development

AWS Development

AWS Development

Google Cloud Development

Google Cloud Development

SQL Programming Development

SQL Programming Development

MySQL Development

MySQL Development

MongoDB Development

MongoDB Development

Big Data

Big Data

Robotic Process Automation

Robotic Process Automation

Social Media Marketing

Social Media Marketing

Search Engine Optimization

Search Engine Optimization

QA Testing

QA Testing

Software Testing

Software Testing

Software Security

Software Security

Maintenance And Support

Maintenance And Support

I.T. Consulting Services

I.T. Consulting Services

Business Intelligence

Business Intelligence

YII Development

YII Development

Data Analysis

Data Analysis

Alexa Skills Development

Alexa Skills Development

On Demand App for Mobile repairing services

On Demand App for Mobile repairing services

On Demand App for Car Service Booking

On Demand App for Car Service Booking

On Demand App for Cleaning Services

On Demand App for Cleaning Services

On Demand App for Pharmacy

On Demand App for Pharmacy

On Demand Dedicated Developers

On Demand Dedicated Developers