We developed the following modules for this project:

Pictures of the installation:

-

This screen shows a picture of the installed solar panels.

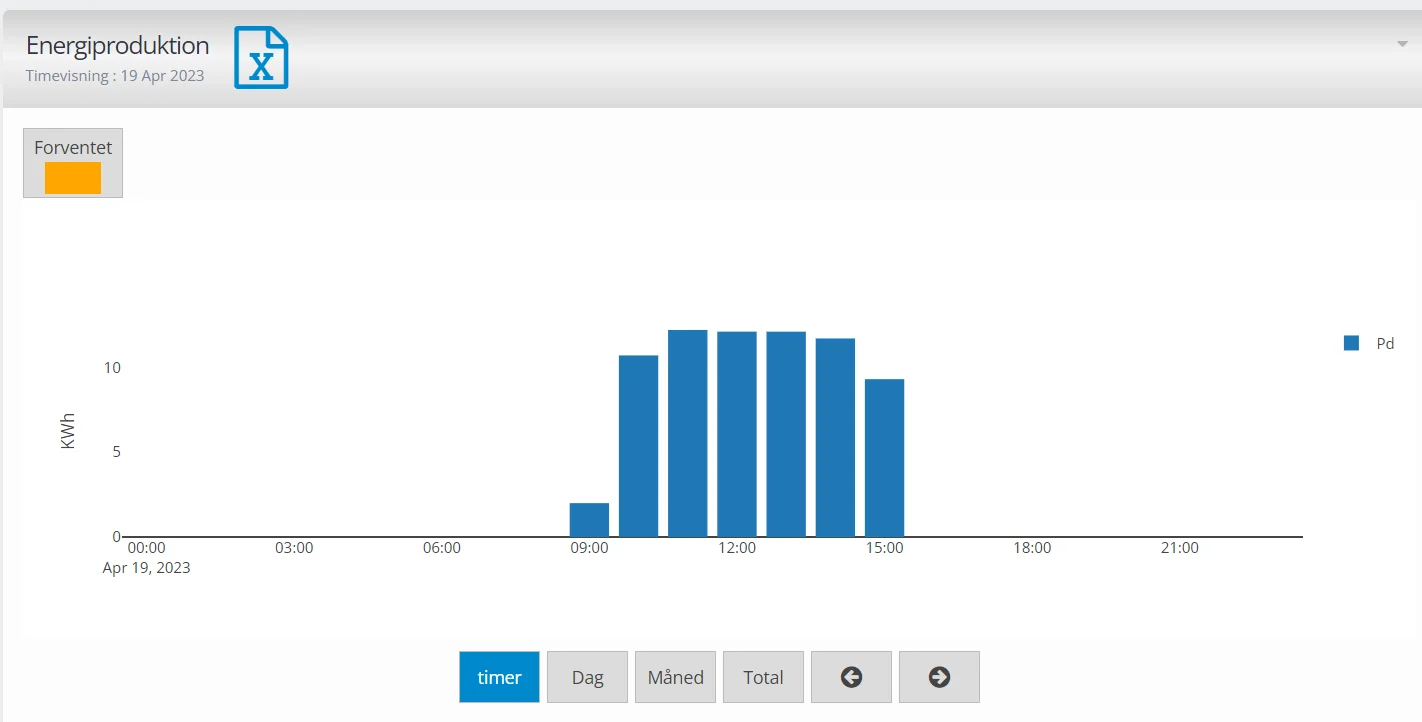

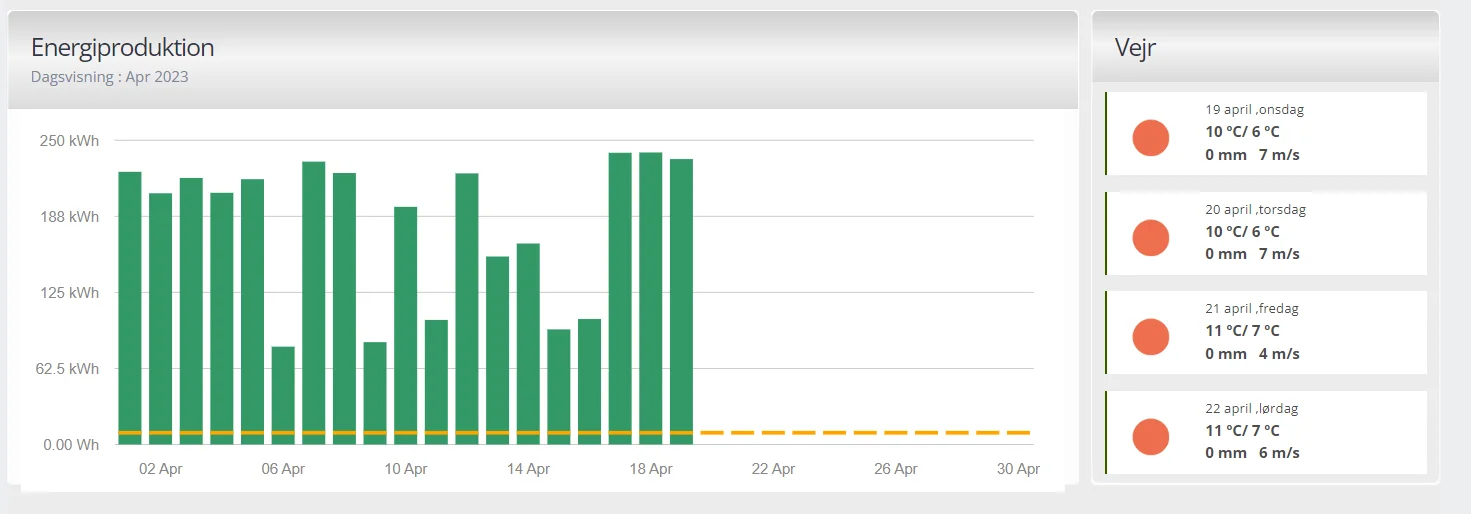

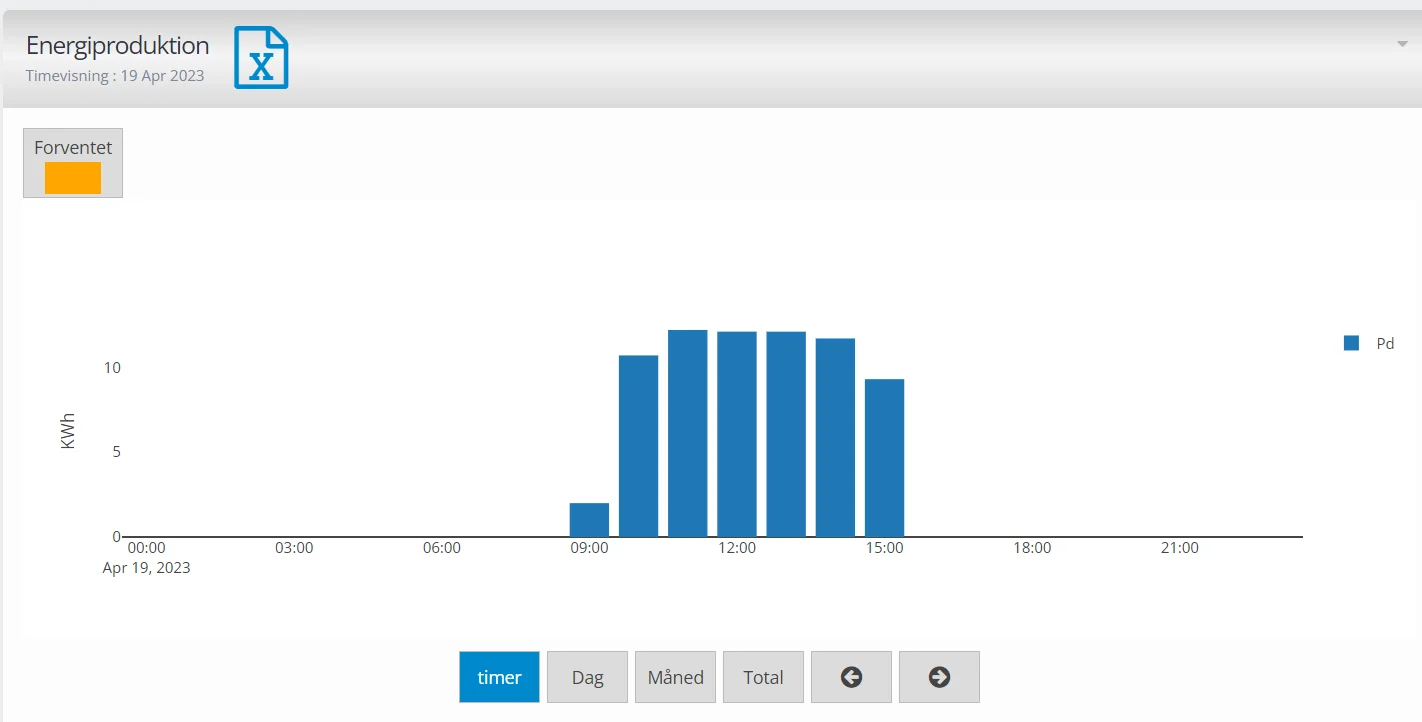

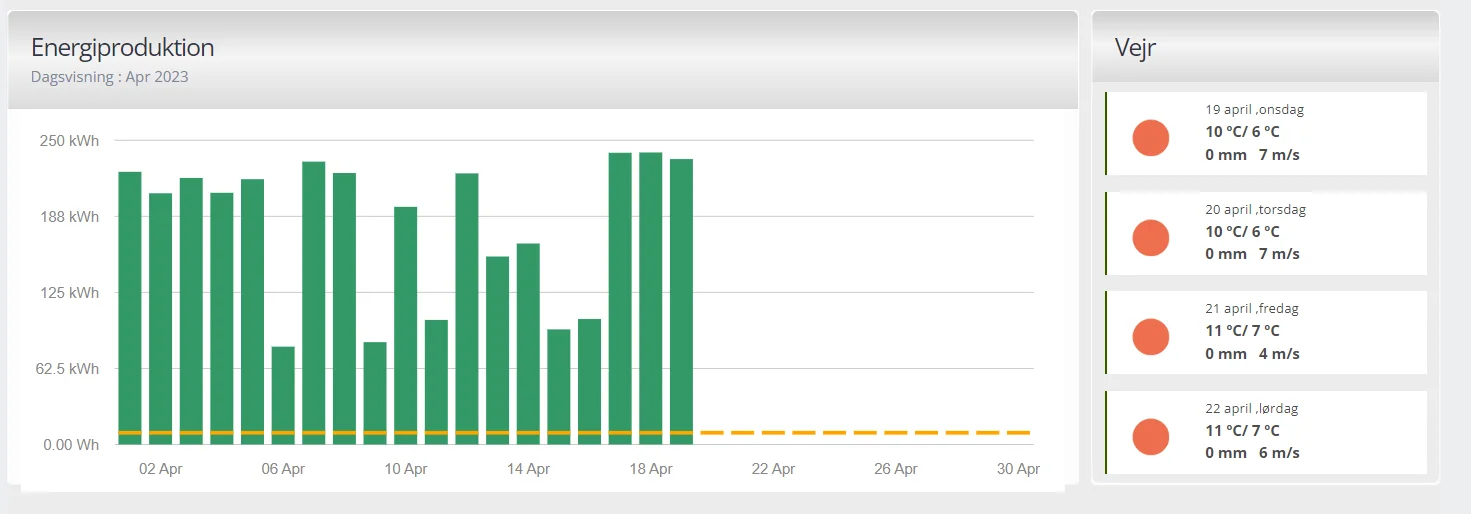

Energy production

-

On this screen, the user can check the overall power generated by the solar panels.

-

Users can calculate the overall power generated by the solar panels per hour, per day, per year, and the total power generated to date.

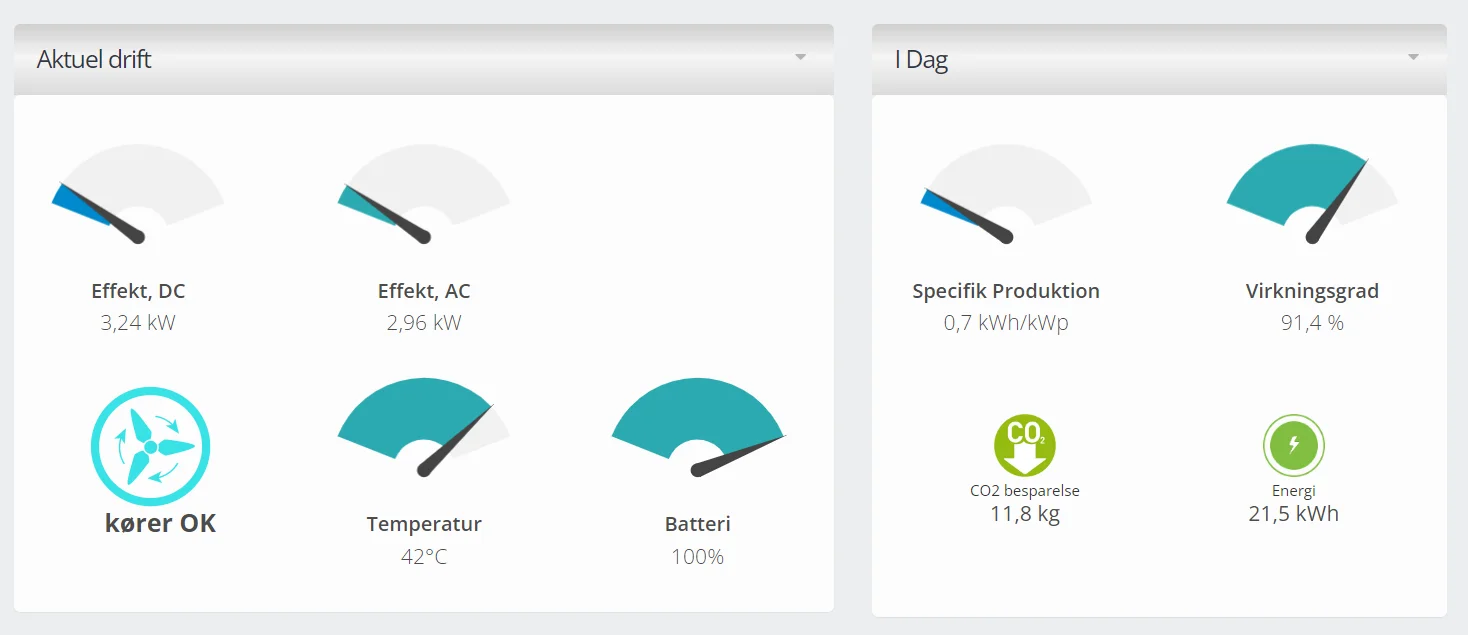

Inverter Status

This segment is divided into four different parts:

-

The first part shows the Number of inverters working in the system/the total number of inverters installed in the system.

-

The second panel shows the number of MPPs running/total number of MPP installed.

-

The third panel shows the stopped inverter/total number of inverter.

-

Fourth-panel show the number if inverter will error/total number of inverters installed in the system

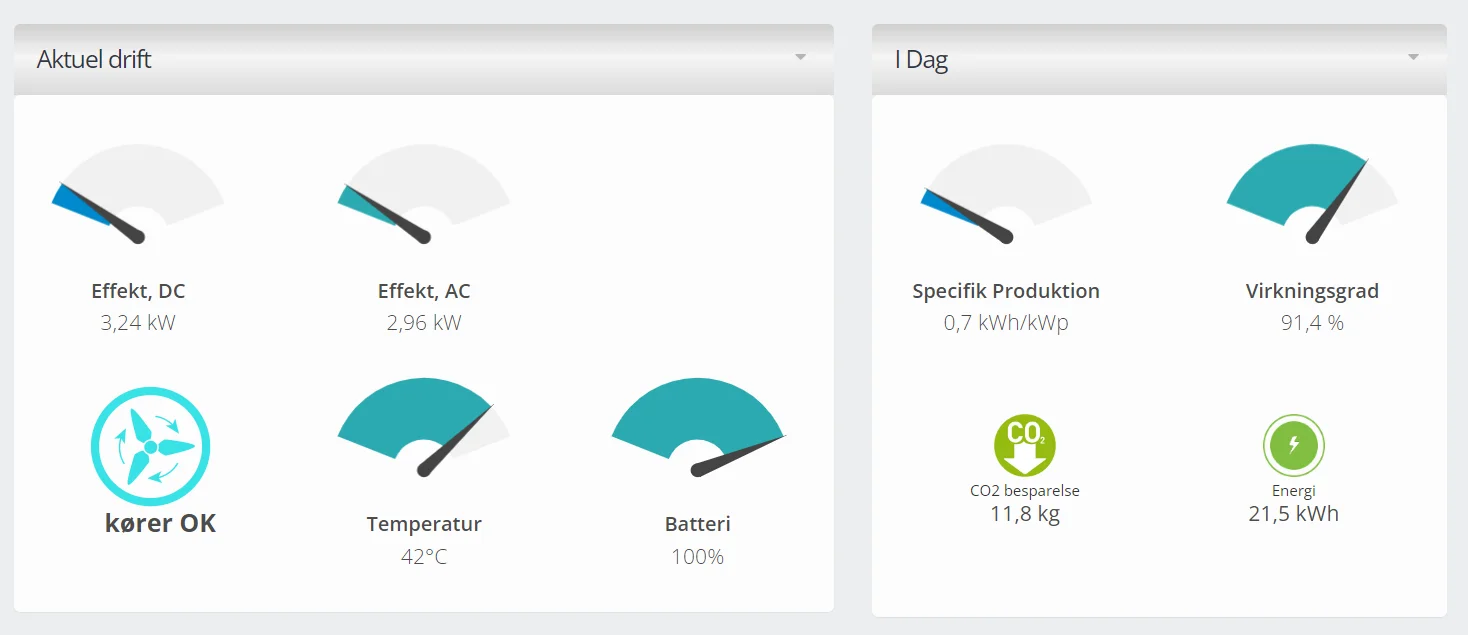

Production

The production screen shows the overall power produced by the solar panels.

CO2 saving

This panel shows the amount of CO2 emissions saved by the generation of solar power.

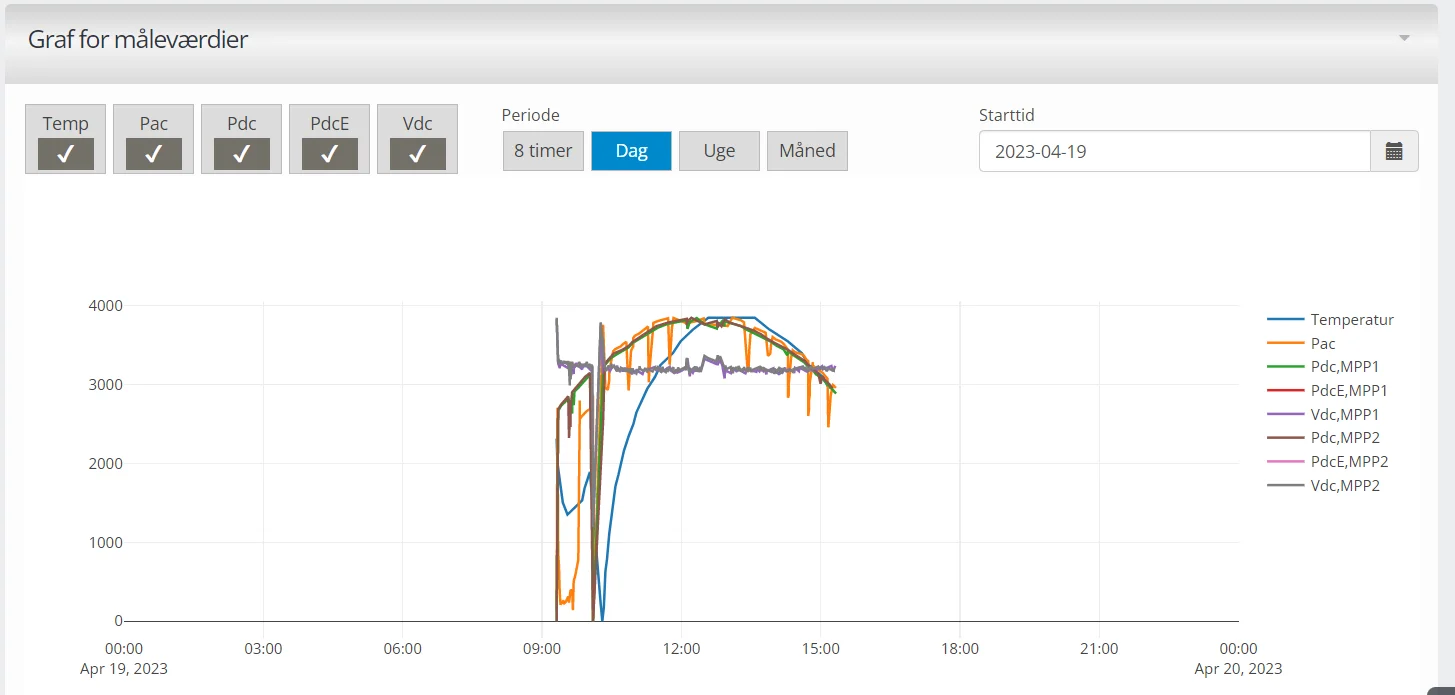

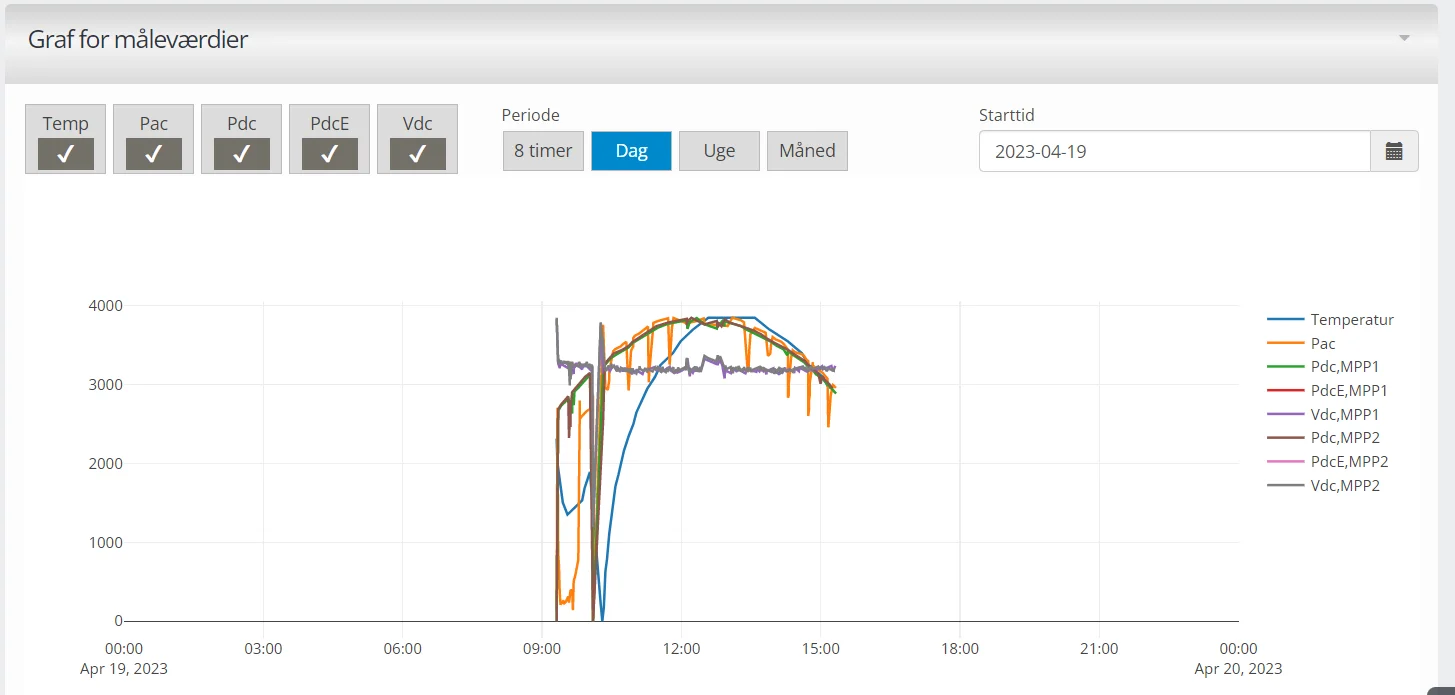

Energy production MPP

Here, MPP stands for "maximum power point." The maximum power point is the point on the current-voltage curve of a solar panel at which it is operating at its maximum power output.

Mean Stack Development

Mean Stack Development

Vue JS Development

Vue JS Development

Javascript Development

Javascript Development

React JS Development

React JS Development

Angular JS Development

Angular JS Development

Next JS development

Next JS development

Java Development

Java Development

Python Development

Python Development

Django Development

Django Development

Cherrypy Development

Cherrypy Development

C# Development

C# Development

ASP.NET Development

ASP.NET Development

NodeJS Development

NodeJS Development

Laravel Development

Laravel Development

CodeIgniter Development

CodeIgniter Development

Zend Development

Zend Development

Ruby on Rails Development

Ruby on Rails Development

CakePHP Development

CakePHP Development

PHP Website Development

PHP Website Development

Symfony Development

Symfony Development

Drupal Development

Drupal Development

Joomla Development

Joomla Development

Wordpress Development

Wordpress Development

.NET Nuke Development

.NET Nuke Development

Kentico

Kentico

Umbraco

Umbraco

.NET MAUI Development

.NET MAUI Development

Xamarin Application Development

Xamarin Application Development

iOS Application Development

iOS Application Development

Android Application Development

Android Application Development

Android Wear App Development

Android Wear App Development

Ionic Development

Ionic Development

Universal Windows Platform (UWP)

Universal Windows Platform (UWP)

Kotlin Application Development

Kotlin Application Development

Swift Application Development

Swift Application Development

Flutter Application Development

Flutter Application Development

PWA Application Development

PWA Application Development

Offshore Software Development

Offshore Software Development

Custom Application Development

Custom Application Development

Front-End Development

Front-End Development

Full Stack Development

Full Stack Development

AI & Machine Learning

AI & Machine Learning

Custom CRM Solutions

Custom CRM Solutions

Flask Software Development

Flask Software Development

Electron JS Development

Electron JS Development

ChatGPT Development

ChatGPT Development

Magento Development

Magento Development

Magento 2.0 Development

Magento 2.0 Development

Magento Enterprise

Magento Enterprise

Shopping Cart Development

Shopping Cart Development

Prestashop Development

Prestashop Development

Shopify Development

Shopify Development

Open Cart Development

Open Cart Development

WooCommerce Development

WooCommerce Development

BigCommerce Development

BigCommerce Development

NopCommerce Development

NopCommerce Development

Virto Commerce Development

Virto Commerce Development

AspDotNetStorefront Development

AspDotNetStorefront Development

RaspBerry Pi

RaspBerry Pi

Firmware Software Development

Firmware Software Development

ESP 32 Software Development

ESP 32 Software Development

Embedded Development

Embedded Development

Internet of Things

Internet of Things

Nordic Development

Nordic Development

.NET Application Development

.NET Application Development

Microsoft Dynamics CRM

Microsoft Dynamics CRM

VB .NET Development

VB .NET Development

Sharepoint Migration

Sharepoint Migration

ASP.NET Core Development

ASP.NET Core Development

ASP.NET MVC Development

ASP.NET MVC Development

AJAX Development

AJAX Development

Agile Development

Agile Development

Microsoft Bot

Microsoft Bot

Microsoft Blazor

Microsoft Blazor

Microsoft Azure Cognitive

Microsoft Azure Cognitive

HTML 5

HTML 5

UI/UX Design

UI/UX Design

Graphic Design

Graphic Design

Adobe Photoshop

Adobe Photoshop

XML Application Development

XML Application Development

Cloud Computing Solutions

Cloud Computing Solutions

Azure Cloud App Development

Azure Cloud App Development

AWS Development

AWS Development

Google Cloud Development

Google Cloud Development

SQL Programming Development

SQL Programming Development

MySQL Development

MySQL Development

MongoDB Development

MongoDB Development

Big Data

Big Data

Robotic Process Automation

Robotic Process Automation

Social Media Marketing

Social Media Marketing

Search Engine Optimization

Search Engine Optimization

QA Testing

QA Testing

Software Testing

Software Testing

Software Security

Software Security

Maintenance And Support

Maintenance And Support

I.T. Consulting Services

I.T. Consulting Services

Business Intelligence

Business Intelligence

YII Development

YII Development

Data Analysis

Data Analysis

Alexa Skills Development

Alexa Skills Development

On Demand App for Mobile repairing services

On Demand App for Mobile repairing services

On Demand App for Car Service Booking

On Demand App for Car Service Booking

On Demand App for Cleaning Services

On Demand App for Cleaning Services

On Demand App for Pharmacy

On Demand App for Pharmacy

On Demand Dedicated Developers

On Demand Dedicated Developers